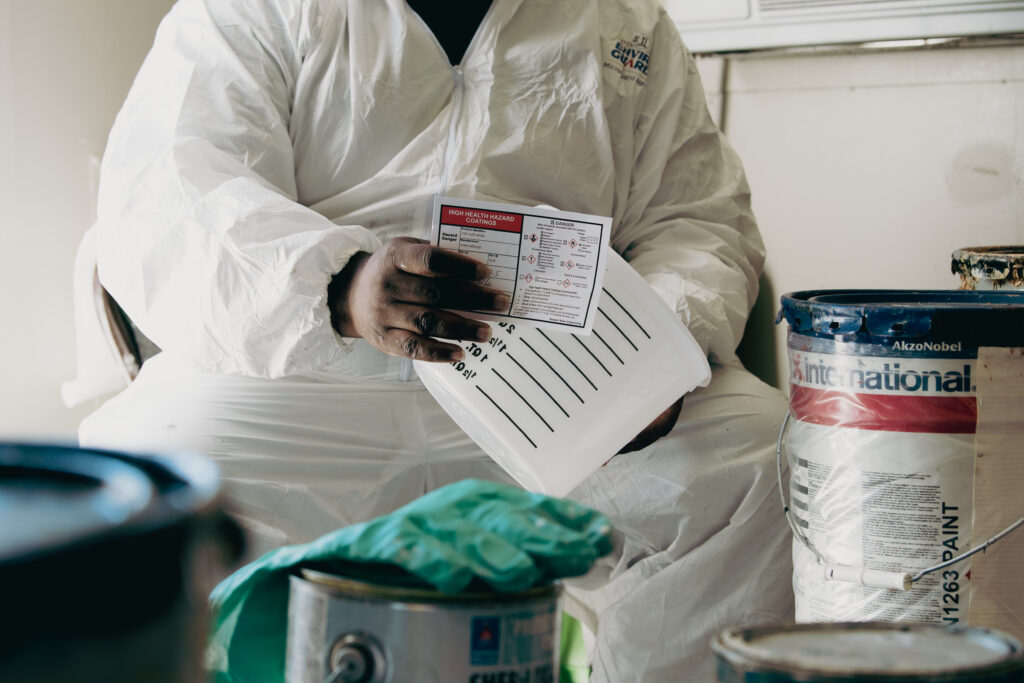

Pictured from left in the back row: Alex Lasky (O27), Rashaad Galloway (X10) and Breanna Hollins (X33). Pictured from left in the front row: Stacie Smelser (X33), Francine Campbell (X33) and Lashawn Nixon (X33). Not pictured: Edward Brown (K45), Edward Brown Jr. (O59), Philip Cantu (O14), Tammy Edwards-Cross (X33), Jerry Diggs (X33), Patricia Dillard (X33), Wayne Hedgepeth (X33), Douglas Miller (X33), Christina Neale (O27), Jamen Neel (O27), George Riddick (O14) and Cody Weston (E33).

Pictured from left in the back row: Alex Lasky (O27), Rashaad Galloway (X10) and Breanna Hollins (X33). Pictured from left in the front row: Stacie Smelser (X33), Francine Campbell (X33) and Lashawn Nixon (X33). Not pictured: Edward Brown (K45), Edward Brown Jr. (O59), Philip Cantu (O14), Tammy Edwards-Cross (X33), Jerry Diggs (X33), Patricia Dillard (X33), Wayne Hedgepeth (X33), Douglas Miller (X33), Christina Neale (O27), Jamen Neel (O27), George Riddick (O14) and Cody Weston (E33). Shipbuilders Improve Safety and Efficiency with Redesigned Paint Label

Published November 5, 2025

A group of Newport News shipbuilders from multiple departments came together to improve an outdated paint labeling system. The new label makes identification clearer, provides more information and keeps shipbuilders safer.

“Safety is our No. 1 priority. The more information a person has, the safer they are and the outcome of producing a quality product goes up. We provided a way to give shipbuilders more information so they can meet those two things,” said Trades Superintendent Alonzo Smith (O69).

The new label lists personal protective equipment (PPE) requirements and relevant hazards and is color-coded for risk. The Reproduction Services team assisted with design revisions, label content and production. The label now includes pre-filled fields. The orientation was updated from vertical to horizontal, creating more space for relevant and important information. It also condenses information that used to be split between two labels into one. “I like that everything’s on one label now. It’s quicker to fill out and keeps production moving in the shop,” said LaShawn Nixon (X33).

Industrial hygienists in Environmental, Health, and Safety (EH&S) evaluate potential hazards that may affect shipbuilders, and that review includes paint regulations.

“We were presented an opportunity to reevaluate how we label and identify paints,” said Alex Lasky (O27), an industrial hygienist and health and safety manager. “The previous labels were not always user friendly and only included basic safety information.”

To begin the project, the team worked with several trades and deck plate shipbuilders to pilot the program. “We knew working with them to gain buy-in and including them in the improvement process was going to be essential to the success of the project,” said Cody Weston (E33), a material process engineer.

The team included shipbuilders from EH&S (O27); Surface Preparation and Treatment (X33); Coatings, Technology and Materials Engineering (E33); Trades Administration (O69); Carrier Production Trades (K47); ISCVN Production Trades (K45); Supply Chain Procurement (O51) and Reproduction Services/Office Services (O14) worked together to review and improve the process.

The new label has received positive feedback from shipbuilders. “One of the best things about the new version of the label is the amount of important information that is now at mechanics’ fingertips. They have the possible hazards of the paint they are using and the proper PPE that will best protect them on the job,” said Francine Campbell (X33).

Foreman Breanna Hollins (X33) agreed that shipbuilders like having PPE listed on the label. “Shipbuilders receive their safety training, but now it is right on the label as a reminder,” she said.

Through teamwork and innovation, these shipbuilders have turned several small changes into a yard-wide initiative that has improved shipbuilder safety.